- Details

- Category: Timesert

- Hits: 31274

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

The lower portion of the tap guide should remain as square as possible to the engine surface. Turn the tap slowly while making sure the guide remains flush. TAP GUIDES |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

For Use in Restricted Areas Time-Sert taps 4mm to 12mm metric / 4-40 to 1/2 inch. |

|||||||||||||||||||

|

Three Larger Sizes in a Convenient Set Time-Sert taps 13mm to 16mm metric / 5/8 to 3/4 inch. |

|||||||||||||||||||

|

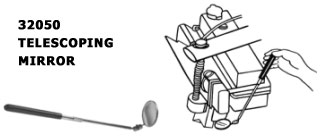

Enables You To See A round Corners |

|||||||||||||||||||

|

||||||||||||||||||||

- Details

- Category: Timesert

- Hits: 29413

Can TIME-SERTs be installed in blind holes?

Yes TIME-SERTs can be installed in blind holes.

A basic dimension we give is .250 inches or 6.3mm deeper hole, than the insert itself.

This is the relief angle length of the tap we have to account for to get a full thread.

This can vary as small taps will have shorter relief angle length than larger taps.

Again this is the length from the tip of the tap to the first "full" thread.

The extra depth also gives us enough room for the install driver to slightly pass thru the bottom of the insert to expand the last few threads, locking it in place.

Example. The blind hole depth for a 5/16-18x.450 should be a minimum of .700 inches or 17.8mm deep.

Insert length .450 + relief angle of tap .250 =.700 inches or 17.8mm Hole Depth.

Another thing to keep in mind when repairing a blind hole application is that you "do not" want to bottom out the driver tool on installation. There is a simple method to safeguard against bottoming the tool out, by placing a visual mark the driver tool.

BEFORE installing the insert, place the driver tool into the hole and mark the tool at the point it can't enter any further. Use a ink marker or even use a small strip of electrical tape around the driver. This way we know exactly how deep the hole is and there is no danger of bottoming the tool out.

- Details

- Category: Timesert

- Hits: 5683

Question:

A common question about repairing drain pans on the vehicle

is how do you keep chips from entering the drain pan?

Answer:

Using some general purpose grease on the drill and tap will help

prevent chips from going into the drain pan. Using a low RPM or

drilling by hand would further reduce the chips into the pan.

Because we are only removing the old threads with the drill, there

will only be a minimal amount of material removed.

Optional tip to keep chips out of the pan would be pouring the old oil

back through pan to flush any remaining chips as it drains.

Also remember the filter is there to catch any debris from normal engine wear.

- Details

- Category: Timesert

- Hits: 29203

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| . | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

- Details

- Category: Timesert

- Hits: 8044

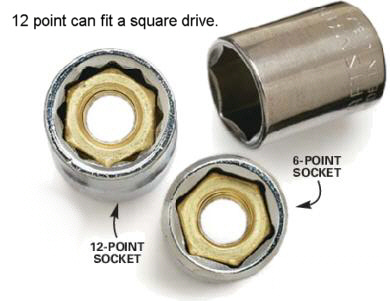

Using 12 point sockets to

turn squares on kit tools :

Our tooling is supplied with square drives.

Normally you would use a TAP-WRENCH on taps or tools with squares.

But you will probably not have enough room for a tap wrench because of

clearance issues with a frame rail or some obstruction. Square drive

sockets are another option. If you do not have square drive sockets you

may optionally try to use 12 point sockets to drive the squares on tools.

12 point sockets generally will hold a square better than a 6 sided socket.

EXAMPLE FOR M14x1.5 DRAIN PAN KIT 12 POINT SOCKETS.

1) Drill square = 1/2 inch 12 point socket.

2) CounterBore square = 7/16 inch 12 point socket.

3) Tap square = 7/16 inch 12 point socket .

4) Driver tool square = 3/8 inch 12 point socket.

This is only one possible solution to turning a tool with a square drive.